By Petra Postolache

Did you know there are around 34.000 sawmills spread around in the EU countries? The majority of them are qualified as small and medium enterprises1, but together these sawmills produce around 80 million m3 of sawn softwood and 5.5 million m3 of sawn hardwood2. France, Germany, and Romania are the largest hardwood producing countries in our neck of the woods.

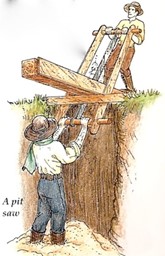

The deciduous forests of Europe have an abundance of oak, maple, walnut, and beech trees that have since the longest times been used by humans for construction, furniture, tools and even jewelry. But turning logs into timber for your builders is a long and complex process, and for many years it was quite dangerous for the people involved.

This month, we want to invite you inside a modern timber factory, where oak logs are transformed into beautiful planks using the latest technology. Global Timber visited a German sawmill back in May 2022, and we want to share a bit from our experience.

A visit at a modern hardwood sawmill

In olden times, working with wood processing would include a fair bit of risk. The job was very manual, and the heavy logs might pose a direct threat to the lives of the workers. However, today it is a very different story as the sawmills have started to adopt more automated machinery that optimizes the process while protecting the workers from harm.

In today’s modern world, all sawmills are industrial units that transforms round logs into shaped pieces (sawn timber, boules, etc.), through longitudinal cutting. Usually, all larger sawmills include the following basic sections:

- A log warehouse

- Manufacturing hall

- Thermal and chemical treatment section

- Timber warehouse

- Associated sections

- Annex sections

The sawmill we visited occupies a surface of 80.000 m2 and includes both air- and kiln-drying designated spaces.

Running a modern sawmill requires consistent investment in new machinery, kilns, and storage facilities. The sawmill we visited had invested in computerized solutions for tasks like debarking the logs, metal detection, and maximizing the yield of the logs. An interesting fact many do not know is that, since trees live for hundreds of years, things like nails, wires and other metals parts can often be found within the wood. At this particular sawmill, they even told us about how they might find shrapnel pieces from grenades embedded in the wood that dates all the way back to wartimes in Germany. These parts need to be removed before sawing, or else they can damage the machines.

Picture: Global Timber

Primary wood-processing

In the production of timber, nothing goes to waste. The bark pieces and sawdust are not thrown away, but instead it can be sold as mulch or used to fuel certain kilns at the sawmill.

Once sorted, logs are cut into different dimensions. These modern saw installations can cut about 20.000 m3 of hardwood logs into sawn timber a year. The timber is then sorted according to dimensions and hereafter, the planks are stacked and ready for a slow and careful air-drying in a large yard. Many sawmills don’t use a kiln for the majority of the drying and will just let their timber air-dry. Others use kilns ovens which can speed up the drying process significantly and thereby, increase the value of the timber.

After the initial air-drying process, the timber is further dried down to the requested moisture content in some modern computer-controlled kilns. During this process, the wood is under permanent control in order to guarantee a constant quality.

Next step is edging and grading of the planks. After being dried to the correct moisture content, the timber will be cut square-edged and then measured and graded according to industry grading rules.

After all these processes, the planks are carefully packed and prepared for the market.

Picture: Global Timber

The challenges of managing a sawmill production are various; especially because there are many steps to go through and these steps are often rather time-consuming. From logs to ready-to-market timber, the timeframe can be as long as up to 2-3 years for a single product. A challenge that the European sawmills experience today is the decline in the of availability of logs and raw materials and the quality of it.

In conclusion, wood processing of logs to timber is something humans have been doing for thousands of years. The technological advancements and the accumulation of experience have made the process very efficient, reliable, and even science based. All of this, so that we can all be provided with qualitative beautiful wood products in our everyday lives.